Wet Scrubber

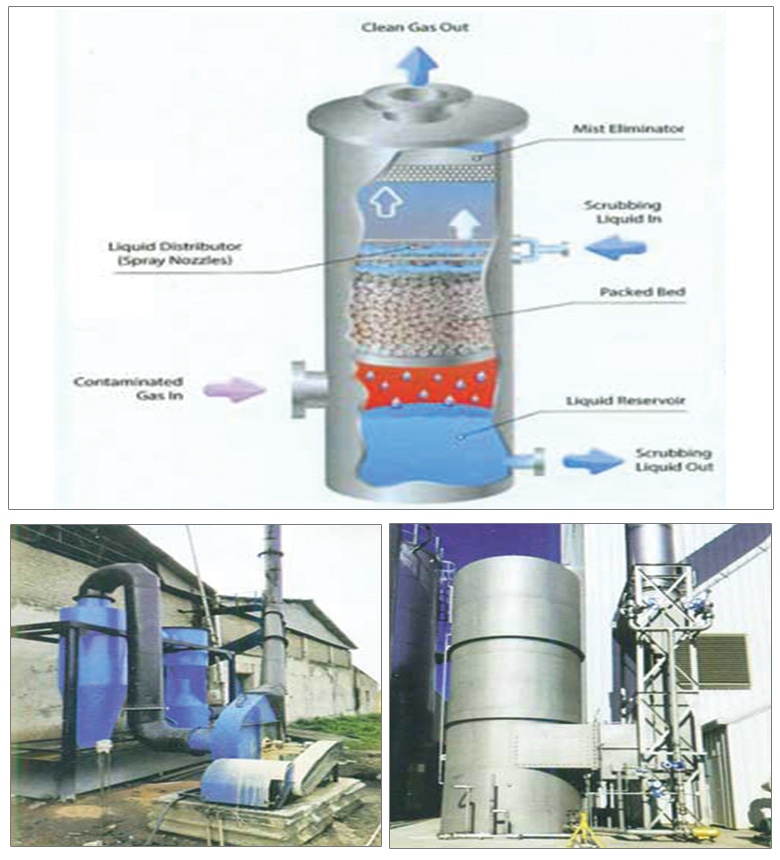

The term wet scrubber describe a variety of devices that removes pollutants from a furnace flue gas, Boiler flue gases or from other gas streams. Ina wet scrubber, the polluted gas stream is brought into contact with the scrubbing liquid, by spraying it with the liquid, by forcing it through a pool of liquid or by some other contact method so as to remove the pollutants.

The design of wet scrubbers or any air pollution control device depends on the industrial process conditions and the nature of the air pollutants involved. Inlet gas characteristics and dust properties (if particle are present) are of primary importance. Scrubbers can be designed to collect particulate matter and / or gaseous pollutants. The versatility of wet scrubbers allow them to be built in numerous configuration, all designed to provide good contact between the liquid and polluted gas stream.

The Wet Scrubbers can be designed with packed bed (using broken porcelains or Charcoal etc.) to increase the exposing time of flue gas through the liquid droplets. The Wet Scrubbers remove dust particles by capturing them in liquid droplets. The droplets are then collected the liquid dissolving or absorbing the pollutant gases. Any droplets that are in the scrubber inlet gas must be separated from the outlet gas stream by means of another device referred to as a mist eliminator or entertainment separator (these terms are interchangeable). Also, the resultant scrubbing liquid must be treated prior to any ultimate discharge or being reused in the plant. Wet Scrubber’s ability to collect small particles is often directly proportional to the power input into the scrubber. Low energy devices such as spray towers are used to collect particles larger that 5 micrometers. To obtain high efficiency removal of 1 micrometer (or less) particles generally requires high energy devices such as venture scrubbers or augmented devices such as condensation scrubbers. Additionally, a properly designed and operated entertainment separator or mist eliminator is important to achieve high removal efficiencies. The greater the number of liquid droplets that are not captured by the mist eliminator, the higher the potential emission levels.

WhatsApp For Best Price

Contact Us